With the rapid development of the industrial manufacturing industry, all kinds of precision instruments are emerging, one after another. There must be no internal flaws in the face of such high-demand precision instruments. At this time, industrial endoscopes are used as non-destructive testing tools. The importance is also getting higher and higher. In the face of such complex testing requirements, industrial endoscope manufacturers must keep pace with the times and launch customized chemical endoscope services.

To better communicate and customize industrial endoscope products, what points and precautions do customers need to figure out:

First, you need to know the environment of the place you are testing, such as whether the testing environment contains liquids such as water, oil, alcohol, eccetera., and whether it is in a unique environment such as high temperature and high pressure. For these needs, you need to clarify whether you need IP68 waterproof or explosion-proof industrial endoscopes; this is the first thing we need to know;

In secondo luogo, it is to understand the aperture and depth of the detected object to determine the required diameter and length, which is an integral part of determining the overall industrial endoscope;

In terzo luogo, it is necessary to know the functions we need. Video recording and photography are the most basic functions. On this basis, there are also special functions such as 3D measurement, defect identification, and WIFI transmission;

Finally, to make a reasonable budget, you must pursue high-cost performance and be clear about the best match you can follow, not high pixels and small diameter. This is enough as long as you meet your needs and solve your problems. The above is the selection points and precautions, and I hope they will be helpful to the customization of industrial endoscopes.

WIFI industrial endoscope principle:

The industrial endoscope host has a built-in WIFI chip. The mobile phone or computer is connected to the WIFI signal emitted by the WIFI chip, connected to WIFI, and then through the XDV general software on the receiving end; after the successful connection with the host, the image can be controlled through the Real-time software transmission to the invalid receiving end, you can take pictures and video operations through XDV software.

How to use WIFI industrial endoscope:

1. Select to turn on WiFi in the menu bar of the host, and you can see the “” sign on the top of the host display, indicating that the WiFi is connected;

2. Turn on the WiFi at the wireless receiving end, search for the WiFi named “CDR_***f”, click to connect, enter the default password “12345678”, and you can use it after the connection is successful;

3. Open the XDV general software installed on the wireless receiving end. After successfully connecting with the host, the detection image can be transmitted to the wireless receiving end in real-time. Users can take pictures and record videos through the XDV software.

At present, more and more devices on the market need to use WIFI for transmission, such as security checkpoints, take photos and videos through industrial endoscopes, and then wirelessly transmit them to the receiving end of the computer to determine whether there are suspicious items. Familiar with the principle and use of WIFI industrial endoscopes. The method can help us better understand and use the WIFI industrial endoscopes.

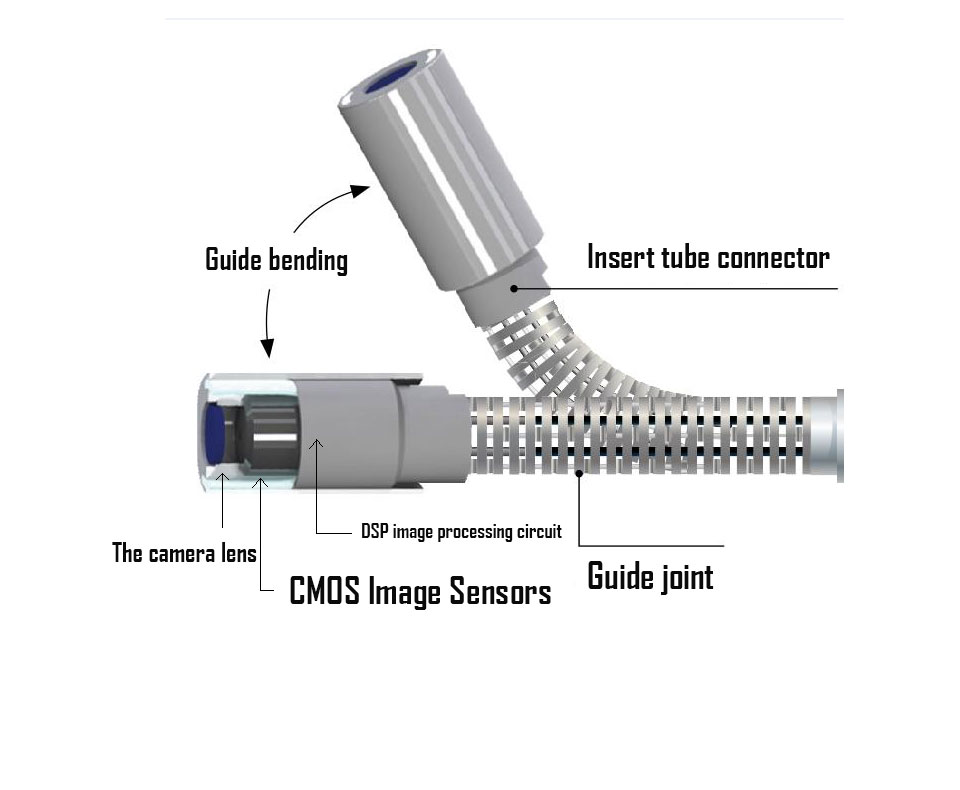

Many people don’t know what the one-way bending angle of the industrial endoscope is when they choose an industrial endoscope. Most industrial endoscopes on our market can turn 360° in all directions without dead ends. A one-way bending angle is extended; that is, a one-way bending angle is added on an all-around basis. This angle range is 0-230°, which means that the current one-way bending angle range is in this range, so how do we determine it? What about the one-way bending angle range we need?

What factors affect the range of one-way bending angles, mainly in the following aspects:

1. The length of the pipeline, longer the distance, the smaller the one-way bending angle. For example, the one-way bending angle range of 10 meters is 0-100°, which is limited by the steel wire rope, so it cannot be bent too much in one direction. ;

2. The bending angle of the pipeline. A pipeline spread flat on the table can achieve the best bending grade, but if it is turned several times, the bending tip of the probe will be significantly affected, and some may even affect the inside of the pipeline. The wire rope is damaged;

3. The thickness of the pipeline, the thinner the channel, the one-way bending angle will also be affected, so the 1.6mm universal industrial endoscope can only have a one-way bending tip of 0-100°, and the pipeline will be damaged if it is giant Internal wire rope too.

The one-way bending angle of the industrial endoscope is determined according to the surface defects inside the object you need to see. Generally, 180° is enough to meet most needs, and the degree of surface defects can be observed without a dead angle, so we don’t need to blindly How much one-way bending angle is required; you only need to choose the angle range you need according to the actual situation.

Many people don’t understand why industrial endoscopes can’t be as long as they want. Now I will tell you a few doubts about why the length of endoscopes with smaller diameters will be shorter and shorter.

This is mainly because The diameter of the pipe limits it. The smaller the diameter of the line, the less space inside the pipeline, which makes it difficult to add at least four wire ropes inside. For example, the pipe diameter of 2mm, its length can only be achieved at most. If it is longer than 5 metri, it will affect the transmission image and cause the small wire rope to be easily broken during the steering process. Quindi, the manufacturer generally stipulates it within the safest range. If it reaches 1.6mm, the length will be shortened to 2.5mm. It’s not that it can’t be made longer; it’s just that this length can make the service life longer, leading to shorter service life.

Another problem, the higher the pixel, the length is within 8mm i.s. Why can’t it be 10 metri? A 2-megapixel lens can only be installed at 8mm, so there is a limit value for such a length to be transmitted longer. Seven meters is the distance that can share clear images. After all, 2 million still. It needs steering, and the space of 7 meters is relatively long. If it is 1 million with steering, the area can be increased to more than 10 metri, but there is also a limit; for example, 15 meters cannot be reached, so that the manufacturer will make it according to customer needs. The customer recommends the appropriate industrial endoscope length.

The tube diameter and pixels limit the length. What I said above is a 360-degree turn to the field of industrial endoscopes. What is not turned is another level. It does not belong to the scope of this explanation. If you need to know more about industrial endoscopes, How to choose the mirror can continue to refer to the relevant content; I believe you can have a deeper understanding of industrial endoscopes.