Industrial videoscopes have become indispensable tools for visual inspection in various industries. These advanced devices offer numerous benefits and play a crucial role in diagnosing and assessing hard-to-reach areas. This article will explore the advantages and applications of industrial videoscopes.

Advantages of Industrial Videoscopes:

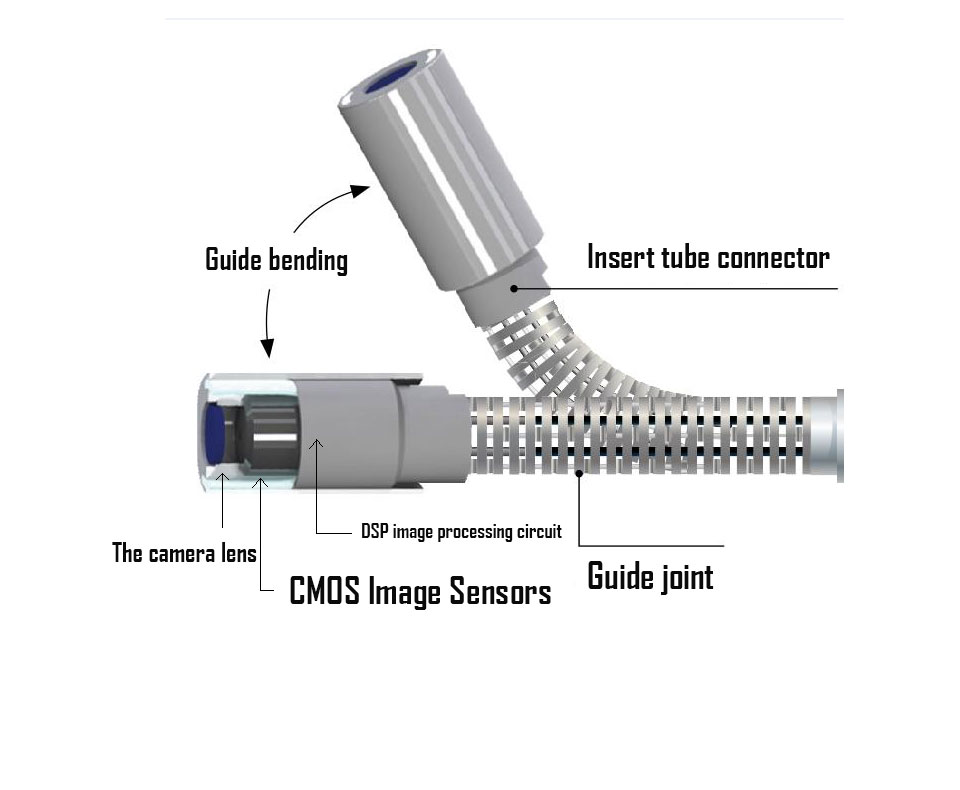

High-Quality Imaging: Industrial videoscopes provide high-resolution images and videos, allowing for detailed inspection and analysis. With advanced camera technology and optics, they offer clear and precise visual information, enabling professionals to detect defects, anomalies, or potential issues.

유연하고 관절적인 프로브: Videoscopes are equipped with flexible insertion probes that can be bent and articulated, providing access to complex and confined spaces. This versatility allows for thorough inspections of pipes, 터빈, 기계, and other challenging areas, reducing the need for disassembly or invasive techniques.

Real-time Remote Viewing: Industrial videoscopes often come with built-in displays or the capability to connect to external monitors or devices. This feature enables real-time remote viewing, allowing multiple stakeholders to observe and collaborate on inspections, fostering efficient decision-making and troubleshooting processes.

Adjustable Lighting: Videoscopes are equipped with adjustable LED lights to provide optimal illumination in various inspection environments. The ability to control the lighting intensity ensures clear visibility and enhances image quality, even in poorly lit or dark areas.

데이터 녹화 및 문서: Industrial videoscopes typically offer recording functionalities, allowing users to capture images and videos during inspections. This capability facilitates documentation, archiving, and sharing of findings, enabling further analysis, 보고, and future reference.

Applications of Industrial Videoscopes:

Manufacturing and Quality Control: Industrial videoscopes are extensively used in manufacturing industries for quality control and inspection of products and components. They help identify manufacturing defects, verify assembly processes, and ensure adherence to quality standards.

Maintenance and Predictive Inspections: Videoscopes play a vital role in maintenance and predictive inspections of machinery, 장비, 그리고 인프라. They assist in identifying signs of wear, 부식, 누출, 아니면 다른 문제, allowing for proactive maintenance and minimizing costly downtime.

Automotive and Aviation: Industrial videoscopes are essential for inspecting engines, 연료 시스템, 파이프 라인, and other critical components in automotive and aviation industries. They aid in detecting faults, monitoring performance, and ensuring compliance with safety regulations.

Energy and Petrochemicals: Videoscopes are widely used in energy and petrochemical industries for inspecting pipelines, 탱크, and other infrastructure. They help identify structural defects, 부식, and blockages, enabling timely maintenance and preventing potential environmental hazards.

결론:

Industrial videoscopes offer a range of advantages, including high-quality imaging, 유연성, real-time remote viewing, adjustable lighting, and data recording capabilities. Their applications span various industries, supporting manufacturing, 유지, 품질 관리, and inspections. 기술이 계속 발전하면서, industrial videoscopes will play an increasingly crucial role in ensuring operational efficiency, 안전, and cost-effectiveness across different sectors.